Tel: 021 951 1211 / info@galvatech.co.za

WHO, WHY AND HOW

GALVANISING

Announcement!!!

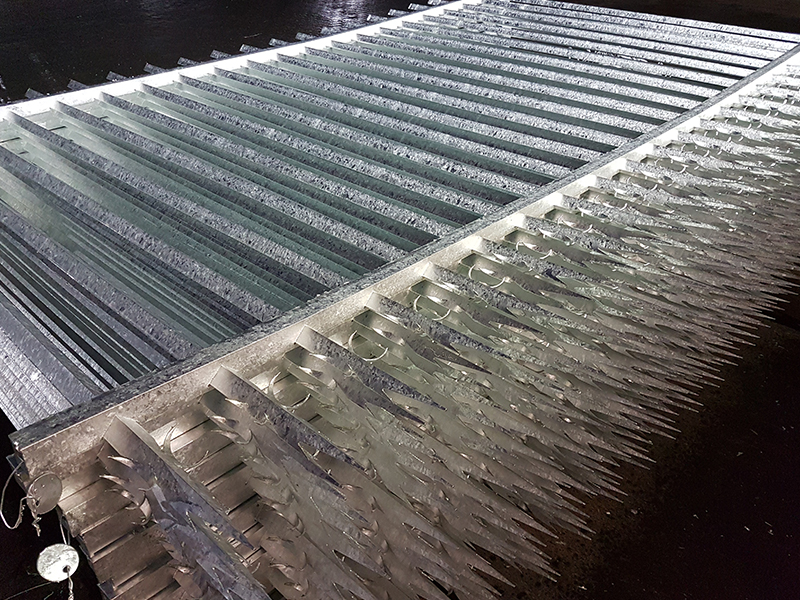

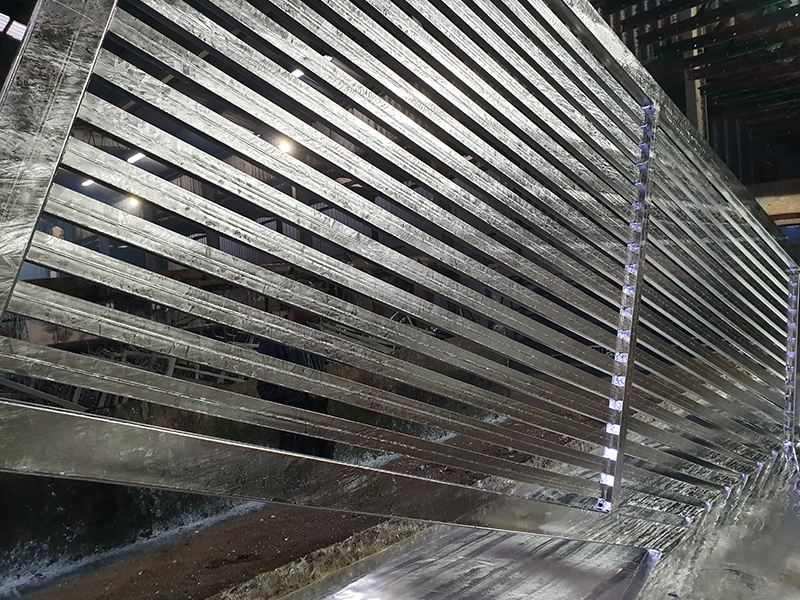

Our newly built state-of-the-art galvanising facility

with it's 14m zinc kettle is now operational.

LENGTH: 14m | DEPTH: 3.2m | WIDTH 1.6m

At Galvatech, our goal is to be your premier partner for corrosion protection. Since founded in 1993, we are committed to delivering high-quality coatings with expedited turnaround times by constantly evaluating and improving our internal processes. Capable of applying duplex coating systems “under one roof,” our services, including Hot-Dip Galvanizing, Grit Blasting, Industrial Painting, Zinc Metal Spraying, and baked powder coatings such as Epoxy, PVC, and FBE, truly enable us to be a one-stop-shop for most of your corrosion protection needs.

With our core business being hot dip galvanizing, 2024 welcomed our newly built state-of-the-art galvanizing facility to Cape Town, South Africa. Centrally located in Bellville South Industrial, our facility has been designed with the latest best practices and 30 years of industry experience and includes a world-class scrubber and white fume extraction system to reduce waste and air emissions.

We have also made provisions for future solar power installations to minimize our environmental impact and improve operating efficiencies. Even though we are certified to provide coatings that comply with SANS 121 / ISO 1461 we have invested in research and technology to produce a high-quality and a visually distinct galvanized coating which set us apart from our competition.

With our new 14m zinc kettle and matching encapsulated pre-treatment process, we are expecting to be one of the most capable galvanizers in the Western Cape. The additional advantage with the newly acquired yard space also affords us the title of “the galvanizer with the largest lay-down area in Cape Town,” which is ideal for customers with large projects such as solar power plants or power transmission pylons.

We welcome inquiries of any size and are ready to assist with projects ranging from small garden gates to large-scale industrial and commercial steelwork. Contact us to learn more about how we can help with your corrosion protection requirements.

Quick Turnaround Time

Our facility is geared to minimise turnaround time.

Competitive Pricing

We strive to offer the best possible products an services and the best possible price.

Excellent Services

We pride ourselves on delivering only the best products and services.

Technical Expertise

Our highly trained staff is ready to assist you with all your blasting and coating needs.

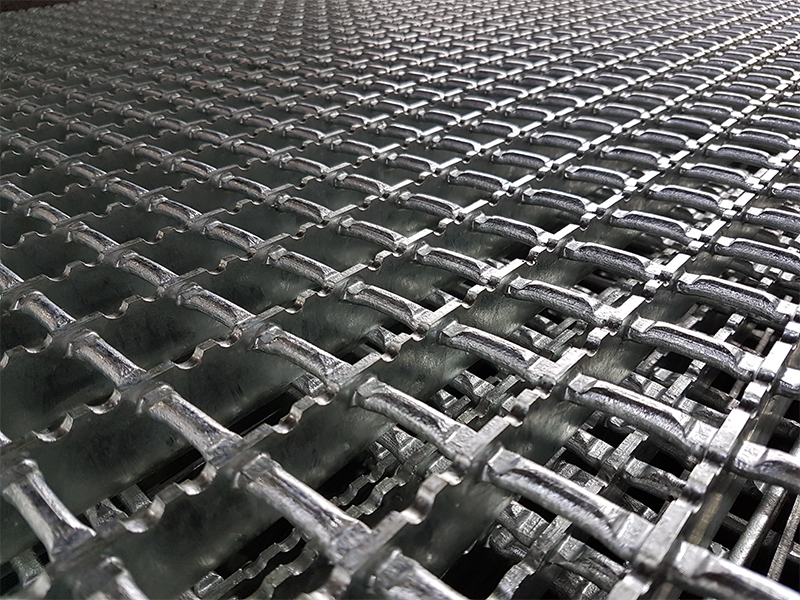

HOT DIP GALVANISING

Hot dip galvanizing is a corrosion protection method for steel and iron structures. The process involves cleaning the surface of the metal, then dipping it into a bath of molten zinc. The zinc reacts with the iron or steel to form a metallurgical bond, creating a protective layer on the surface. This layer provides a barrier against corrosion and rust, extending the life of the metal.

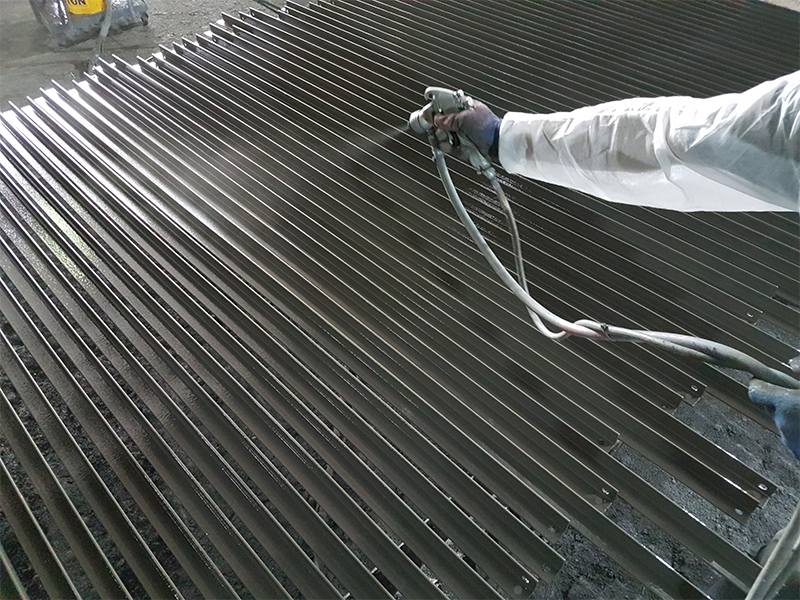

ZINC METAL SPRAYING

Hot zinc metal spraying is a corrosion protection process where a layer of zinc metal is formed on the steel’s surface by spraying atomised zinc onto it. The sprayed zinc material reacts with the metal surface, forming a protective layer that acts as a barrier against corrosion. This method is commonly used in industrial, construction, and marine applications, and is known for its high level of durability and long-term protection against corrosion. Being a listed process that requires special licensing from the City of Cape Town, Galvatech is authorised to apply these coatings.

SHOT OR SANDBLASTING

Industrial shot or sandblasting is a surface treatment process where a high-speed stream of abrasive material is directed onto a surface to remove contaminants, rust, paint, or other coatings. Blasting is the preferred surface preparation method for applications of new paint systems. The abrasive material we use is either garnet or steel grit, depending on the desired profile for the application.

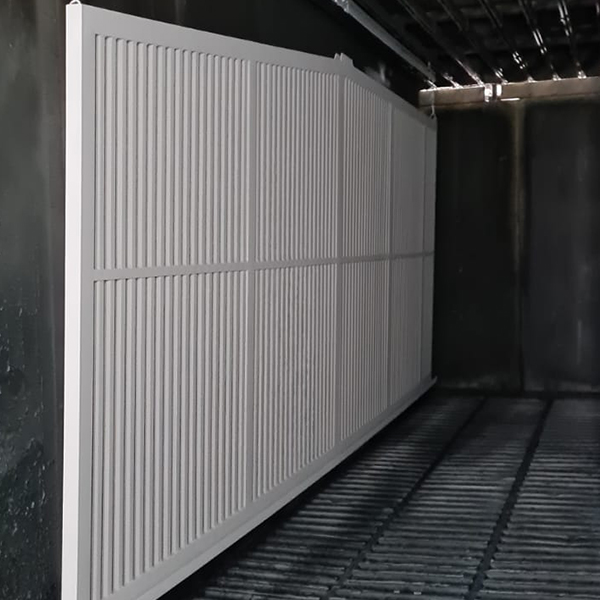

SPRAY PAINTING

Conventional wet spraying is a coating method where a liquid material is applied to a surface using a spray gun. This process results in a uniform, smooth, and consistent finish. This method is commonly used in industrial and architectural applications, and offers protection from environmental factors such as corrosion and UV light. With a wide range of products available, conventional spray painting can offer solutions to almost any application. We recommend sand or shotblasting prior to application to enhance adherence.

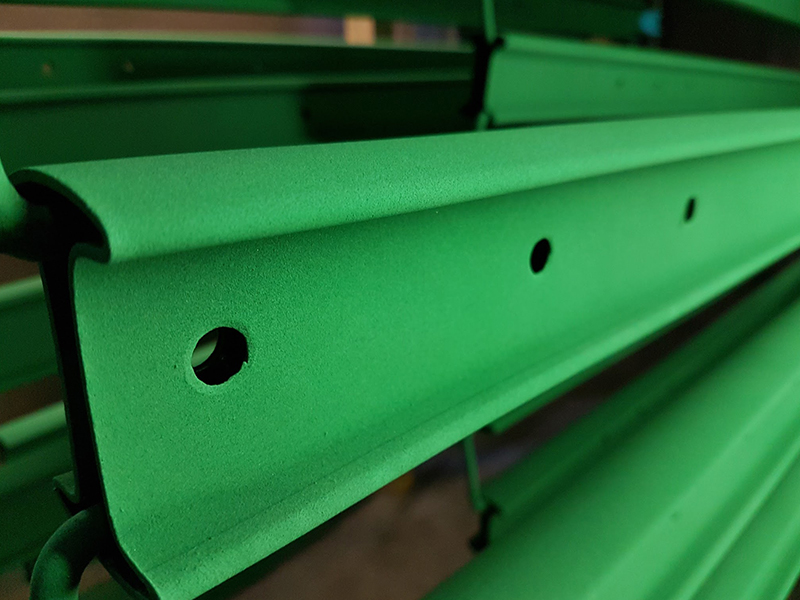

POWDER &

PVC COATING

Powder coating is a metal finishing process where a dry powder material is electrostatically charged and then baked onto a metal to form a hard, durable finish. This method offers protection from environmental factors such as corrosion, fading, and chipping and provides a consistent, uniform appearance. Powder coating is often used in industrial, residential, and architectural applications. Normally used to coat internal balustrading or steel ornaments for decorative finishes with low exposure to harsh corrosive environments.

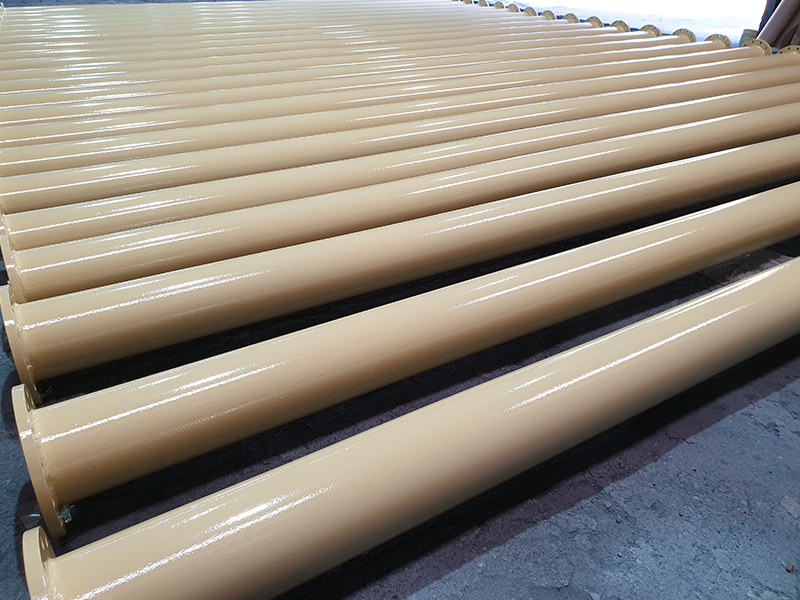

FBE COATING

FBE (Fusion Bonded Epoxy) coatings are widely used in the pipeline industry for corrosion protection and enhancement of pipeline service life. FBE coatings are tough and provide excellent resistance to environmental factors such as chemical exposure, temperature changes, and impact. Once applied, it requires minimal maintenance, making them a cost-effective solution for long-term protection. The time from application to the curing process is incredibly fast compared to wet sprayed applications and FBE coatings help improve the flow characteristics of pipelines, which can increase the efficiency of pipeline operations.

Quick Turnaround Time

Our facility is geared to minimise turnaround time.

Competitive Pricing

We strive to offer the best possible products an services and the best possible price.

Excellent Services

We pride ourselves on delivering only the best products and services.

Technical Expertise

Our highly trained staff is ready to assist you with all your blasting and coating needs.

Grit Blasting Booth

Length: 15m

Width: 5m

Height: 5m

Powder Coating Oven

Length: 7.4m

Width: 1.6m

Height: 2.6m

Galvanizing Kettle

Length: 14m

Width: 1.6m

Depth: 3.2m

What our

clients say

Galvatech (Pty) Ltd

52 Sacks Circle, Bellville, 7530

Cape Town, South Africa

- 021 951 1211

- 066 474 6967 (Whatsapp)

- info@galvatech.co.za

Office Hours

Monday – Thursday: 07:00 – 16:45

Friday: 07:00 – 14:45

Saturday: 08:00 – 11:45

Sunday: Closed

Factory drop off / Receiving Hours

Monday – Sunday: 07:00 – 22:00

Please contact us for opening & closing times on public holidays.

52 Sacks Circle, Entrance via Van der Bijl Street or Sacks Circle

Designed & Developed by Organised Pixels.